Intro

Promo (MP4)

Water electrolysis is the process of extracting hydrogen and

oxygen gases from water solutions by means of splitting the water with an

electrical current.

In particular, in alkaline water electrolysis, water

contains alkaline minerals such as

potassium hydroxide which has a high PH value and high ionic conductivity.

Industrial scale Electrolysis is carried out by utilizing stacks of electrolysis cells.

The majority of commercial water electrolyzers have high

costs associated with their manufacture. Current systems include combinations

of expensive materials that may include rare-earth metals, precious metals, and

metal alloys in the electrode materials. Additionally, current electrolysis

cell designs are generally made of many components assembled into a cell by

hand, resulting in multiple component manufacturing and assembly steps with

high costs from manufacturing and assembly. As one example and without being

limiting, water electrolyzers include bi-polar plates, among other components.

The bi-polar plates are primarily made of electrically conducting material and

of appropriate size and shape to separate streams of anode and cathode fluids

passing over the electrodes. Prior to the present invention, the electrolyzers

also included separate current collectors coupled to the bi-polar plates.

Making at least those components more efficiently would provide for

satisfactory operation with reduced manufacturing cost. For example, both

components are made separately and then joined together. Making them of a

single plate would be more efficient.

What is needed is a better way of making electrolyzer cells and stacks of

such cells. The improved cells and way of making those cells should overcome

the above-mentioned limitations of expensive materials, reduce the number of components

as well as expensive manufacturing procedures and labor costs.

At BullX Research Lab these problems are addressed by utilizing a number of new proprietary techniques

(White paper).

Work

H2 Generation Technology has an objective to provide a better way of making electrolyzer

cells and stacks of such cells as well as reduce associated costs in materials and labor.

These objectives are achieved with a proprietary technology developed at

BullX Research, LLC, which provides improved electrolyzer cells and a

new way of making those cells that overcome the limitations of expensive

materials, numerous components, expensive manufacturing procedures and labor

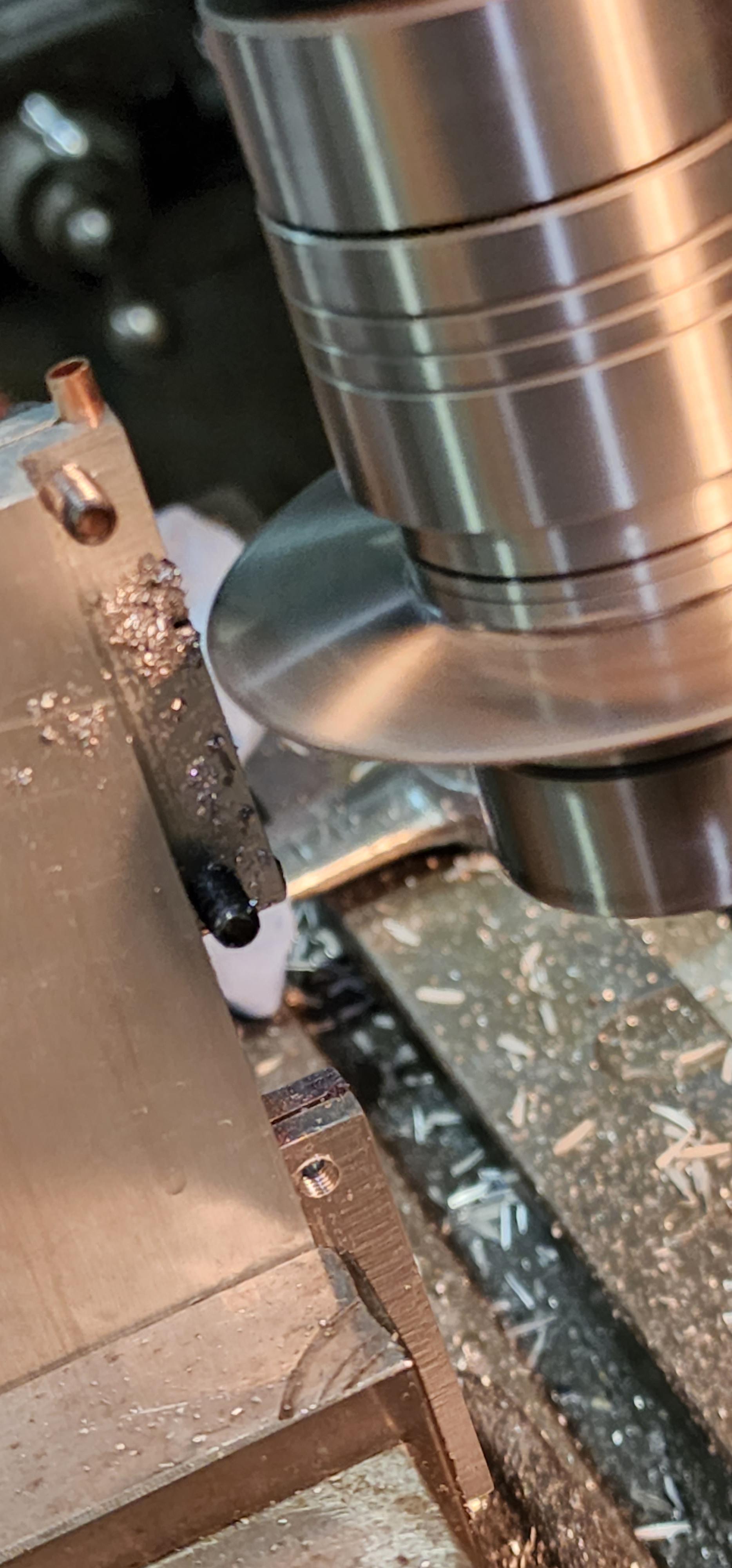

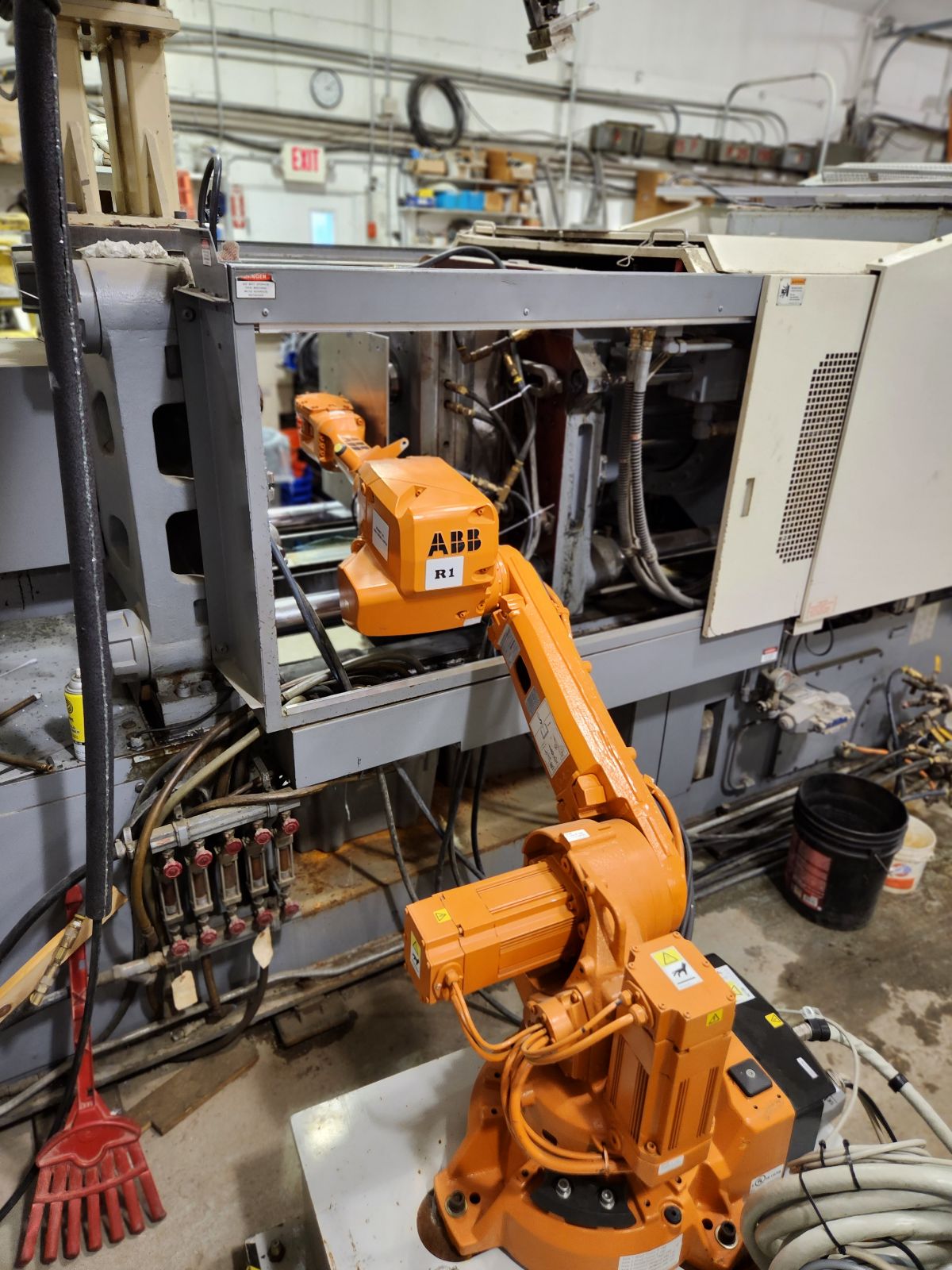

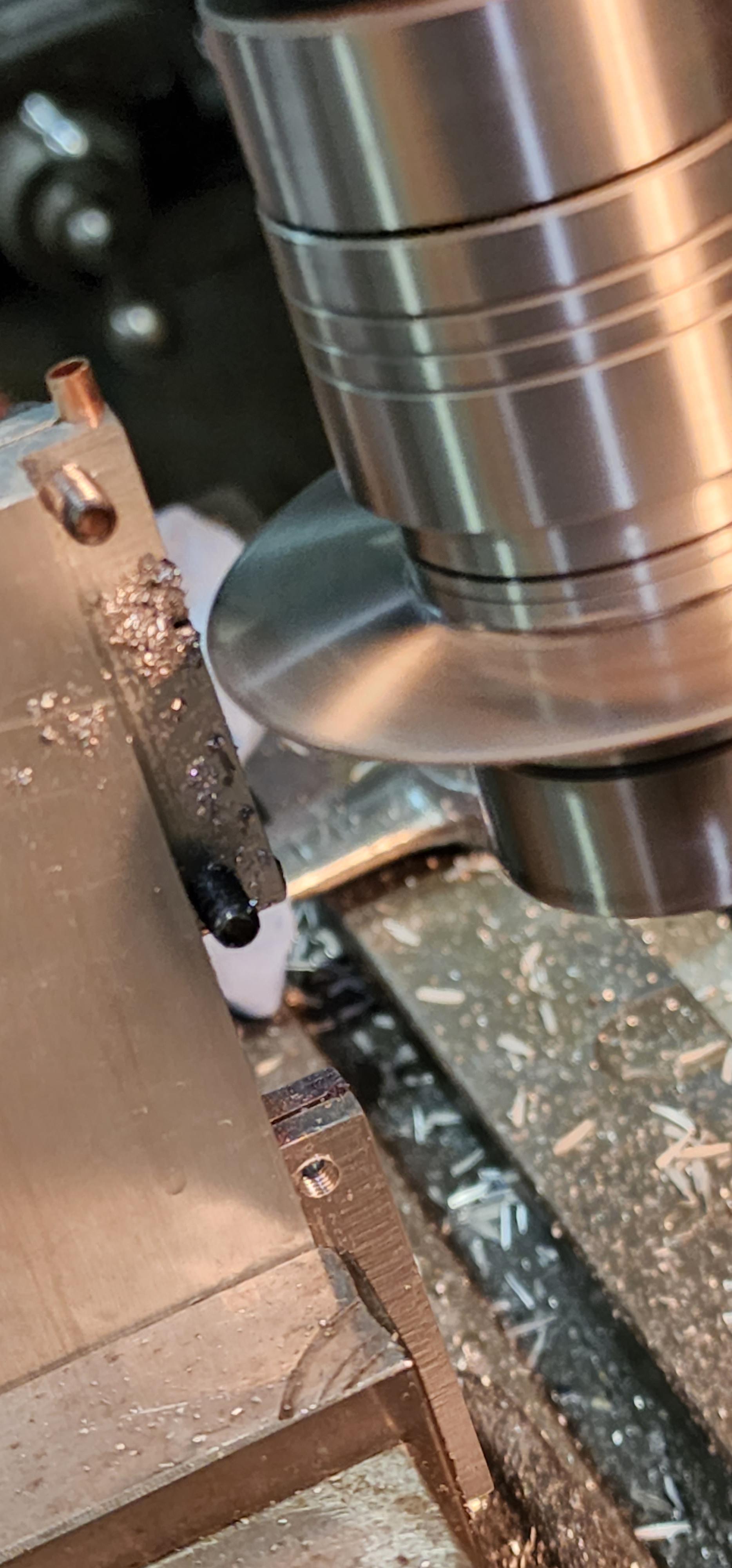

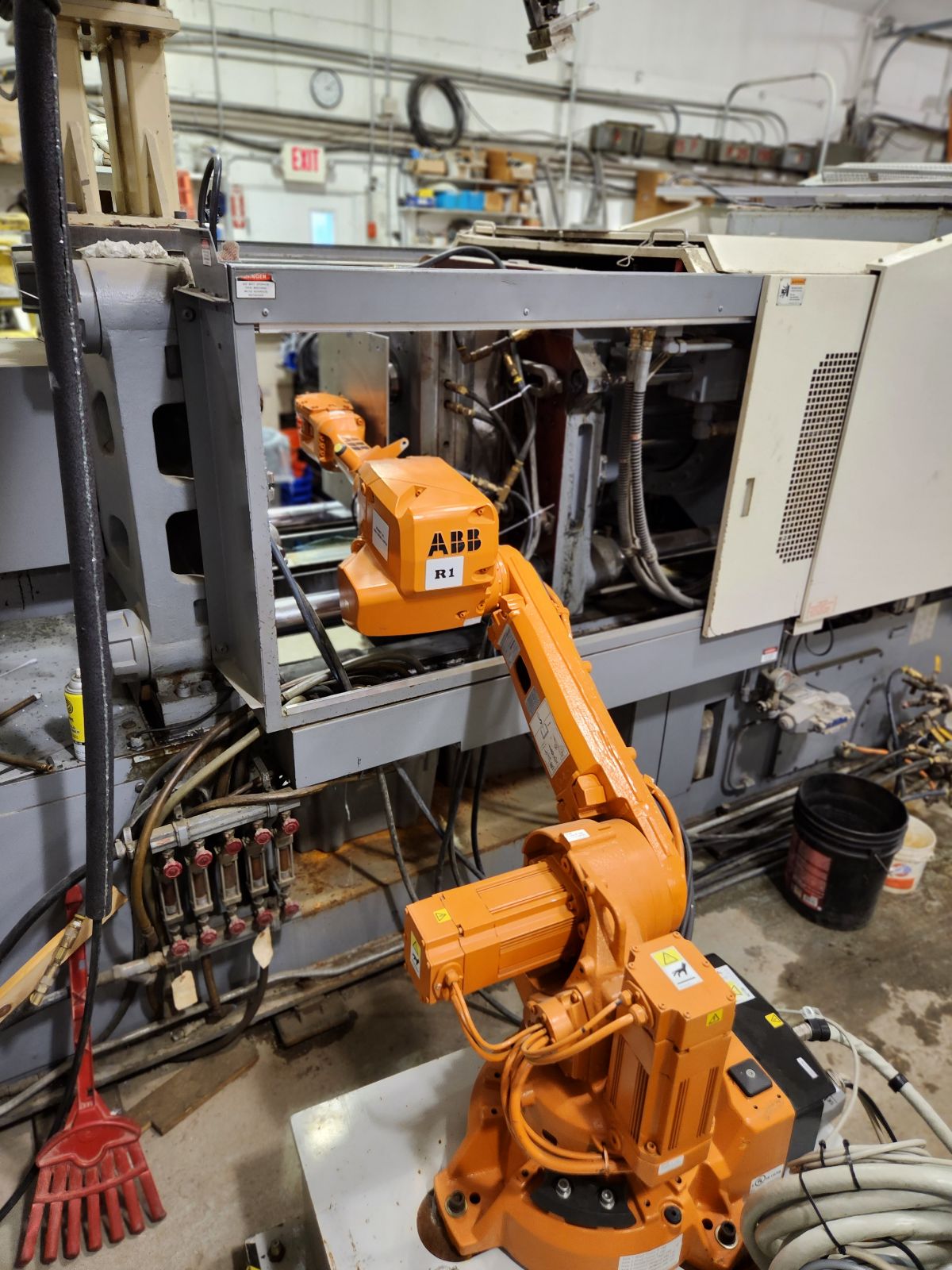

costs. By use of these techniques to form much of the electrolysis cell and

sealing structure, the integration of numerous features and components can be

realized which results in fewer parts and high degree of automation leading to

reduced labor costs associated with electrolysis cell and stack manufacture and

assembly.

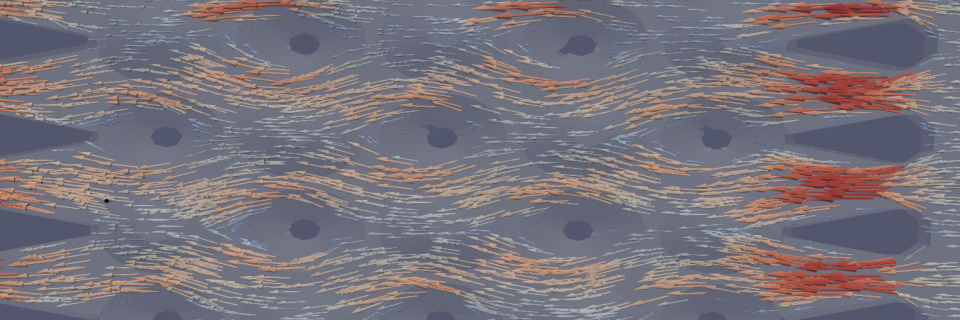

Fluid dynamics modeling capabilities with open-source

(OpenFOAM)

and commercial

(Fluent)

software provide the insight into optimization of cells and cell stacks.

More: Whitepaper,

Market Analysis,

Commercializatin Plan,

Promo Video (WEBM)

Related projects

About

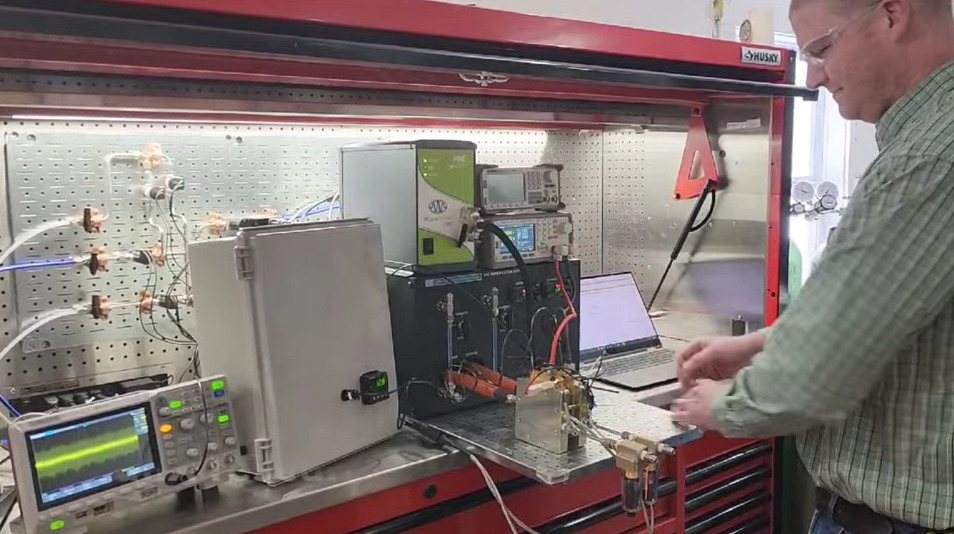

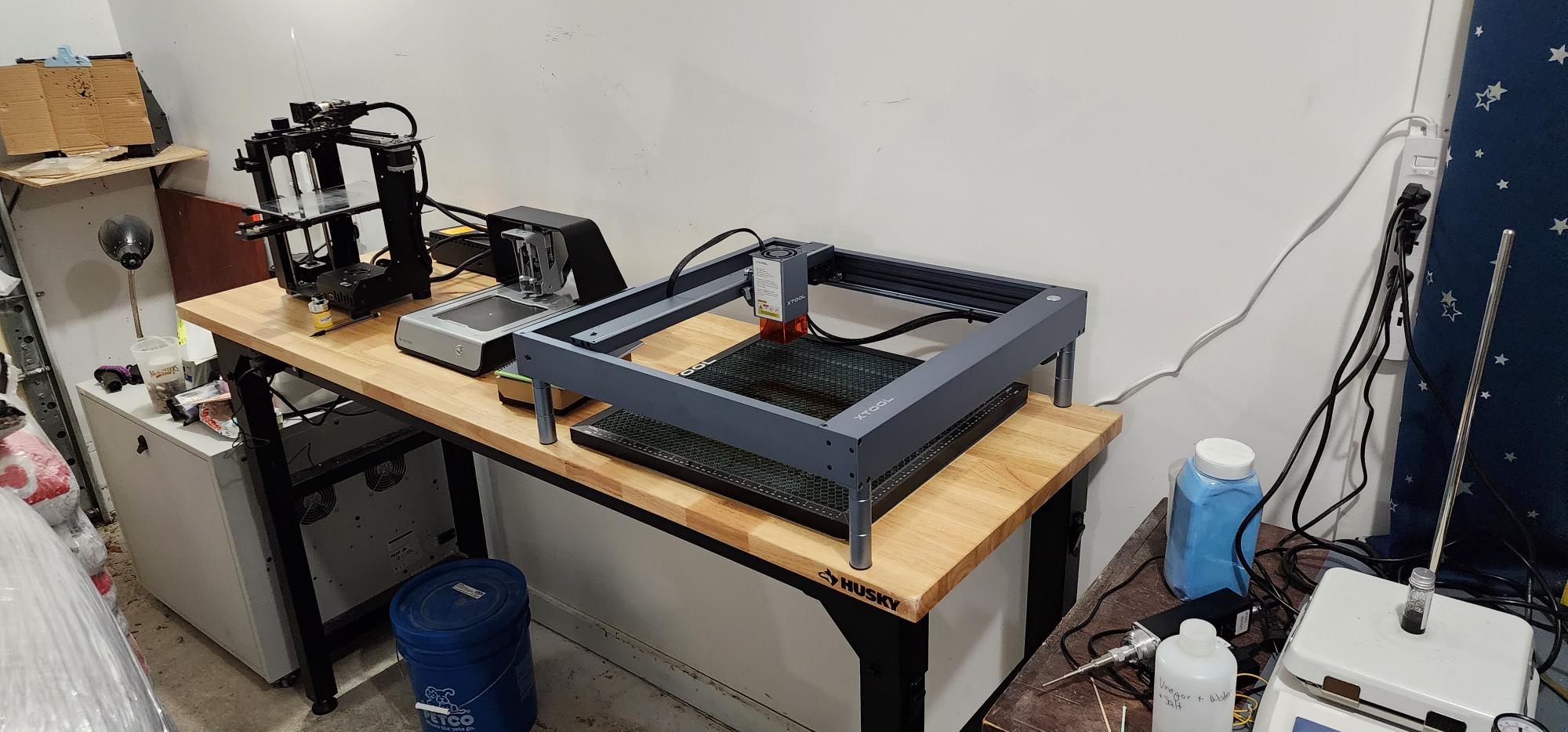

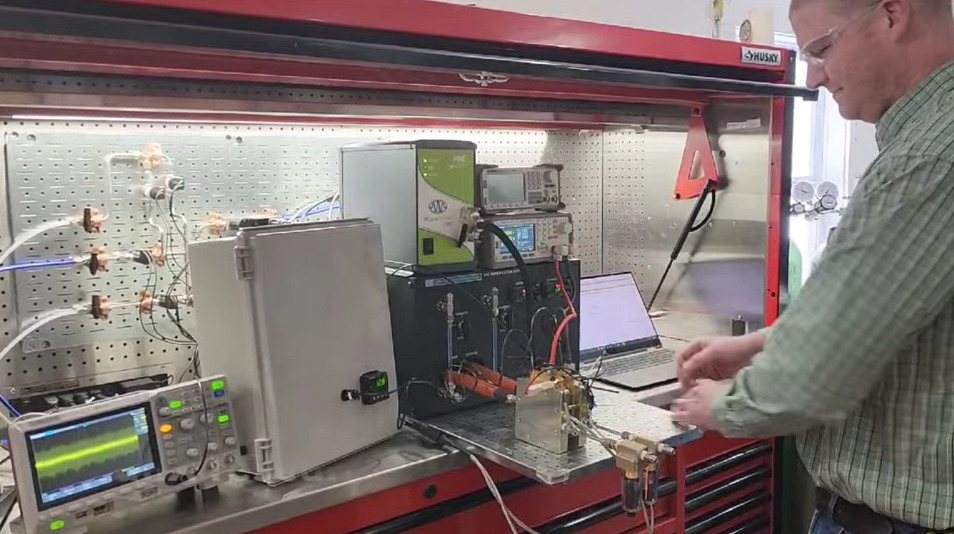

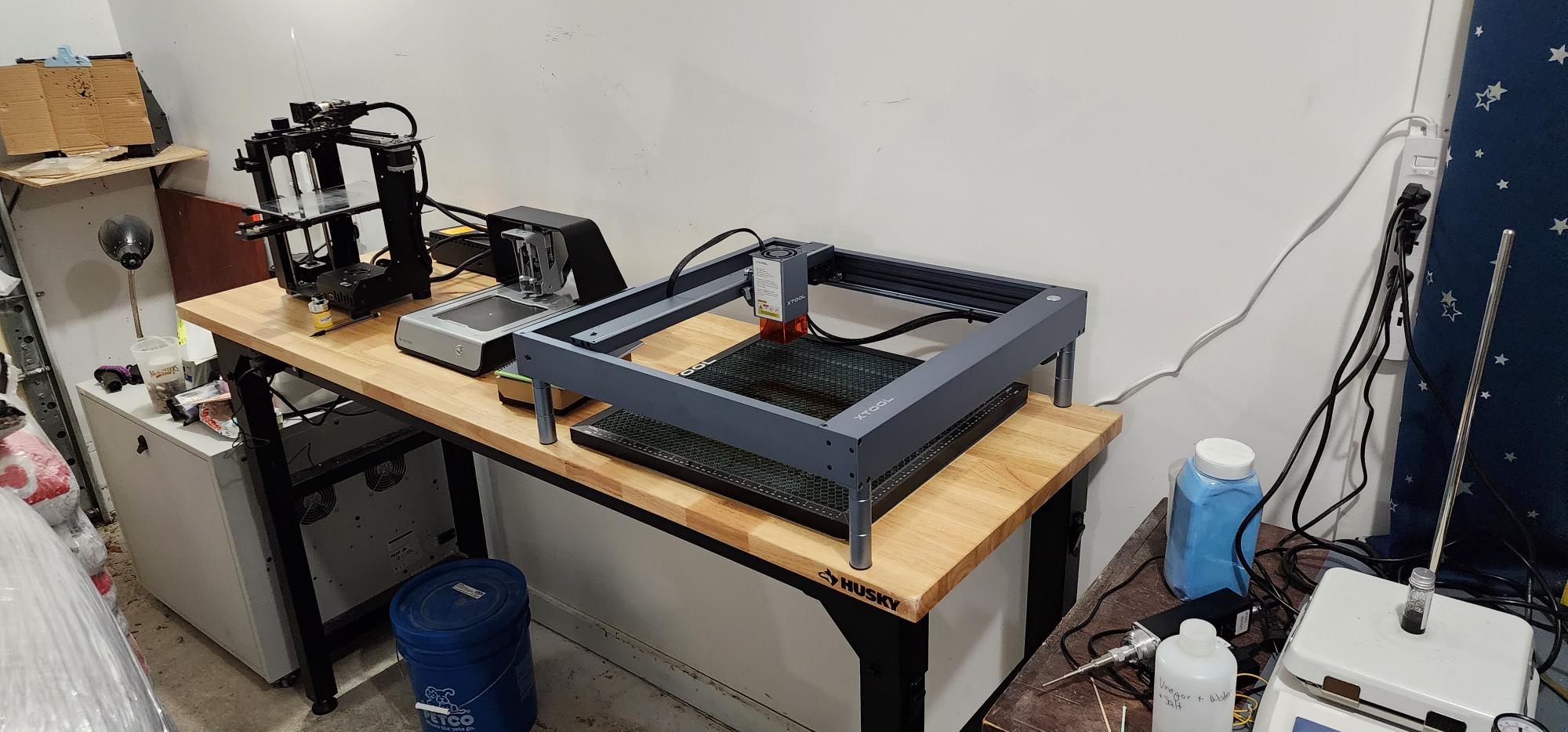

All members of the team have PhDs in the area of chemistry, fluid dynamics, and control systems with accumulated 40 years of experience in conducting experiments and computational modeling in the areas of fuel cells and hydrogen production. In-house testing and manufacturing facilities are available for prototype building and testing.

Recently conceptualized proprietary method of drastically reducing the costs of electrolysis is currently being tested at in-house facilities. The proposed technology has a great potential for automation and quick production scale-up.

Contact

Meet the Team

Brian Bullecks, Ph.D.

Chemical Engineering

- 15-years experience in electrochemical systems (fuel cells, electrolysis, batteries)

- Cell, stack and component level development and testing

- Process engineering and CFD/Electrochemical modeling

- Market research, technical and financial feasibility studies, red flag studies and technical due diligence for investment of hydrogen projects and technologies

- Business development

- FuelCell Energy, Mott MacDonald, BullX Research (current)

Andrei Smirnov, Ph.D., P.E.

CFD, Multi-Physics, Analytics

The Significant Other... Ph.D.

Chemical Engineering

15+ years of industrial experience in the field.

Message Sent

Thank you for Your message!

Sending Failed

Sorry, your message failed. Please contact admin.